Peanut butter belong to liquid material’s precision processing. This commercial peanut butter machine belong to GMS series grinder which is used for liquid material’s precision processing, it integrates the multifunction of homogenizer, impact mill, ball mill, three-rollers mill, shearing mill and mixer etc, it has predominant advantage on superfine grinding, emulsification, homogenization and mixing. The finished products can reach to 2-50um after processing.

|

|

|

Working Principle

- This machine is by the different geometry of the stator and the rotor rotating at high speed under the relative motion, by cutting, grinding, high-frequency vibration and get broken.

- There are three ways of grinding zone in the broken room, the first one is a thick grinding zone, the second one is finely ground area, the third one ultrafine grinding zone by adjusting the stator gap will affect the desired effect (also can be ultrafine processing cycle).

- The machine have compact structure, smooth operation, low noise, corrosion-resistant, easy to clean, easy maintenance features.

- This peanut butter grinding machine is characterised by high degree of automation, great reliability, sealing production and non polluted.

Principal Technologic Parameters

| Model |

Capacity

|

Granularity

|

Power

|

Net Weight |

Outside Dimension

|

|---|---|---|---|---|---|

| GMS-80 |

10-100kg/h

|

2-40 micron

|

4KW

|

210KG

|

680*380*930mm

|

| GMS-85 |

100-250kg/h

|

2-40 micron

|

5.5KW

|

180KG

|

1050*300*840mm

|

| GMS-130 |

250-500kg/h

|

2-50 micron

|

11KW

|

420KG

|

1000*440*1050mm

|

| GMS-130B |

250-500kg/h

|

2-50 micron

|

11KW

|

420KG

|

1000*440*1050mm

|

| GMS-180 |

500-800kg/h

|

2-50 micron

|

18.5KW

|

450KG

|

981*476*1124mm

|

| All Model | 380V, 50HZ, 3phase | ||||

Main application of peanut butter grinder is making peanut butter. And there are other applications:

- Food industry: Aloe, pollen, pineapple, peanut, sesame, fruit tea, icecream, moon cakes stuffing, butter, jam, juice, soybean, soy sauce, bean paste, peanut milk, Protein milk, soy mil, all kinds of Beverages, essence, chicken bones, pigskin etc.

- Chemical industry: paintings, Pigment, die, paint, lubricants, grease, diesel, oil catalyst, emulsified asphalt, Adhesive, detergent, Plastic, Explosives, FRP, leather, emulsified explosives etc.

- Daily chemical: toothpaste, detergent, shampoo, shoe polish, Cosmetics, Bathing precision, soap etc.

- Medicine: syrup, herbage medicine, Paste pharmaceutical, Biological Products, fish liver oil, Vaccine etc.

- Construction industry: All kinds of pigment

- Others: Plastic industry, textile industry, paper Industry, bio chemical Industry, Environmental Protection& energy saving etc.

Peanut Butter Machine Processing Video

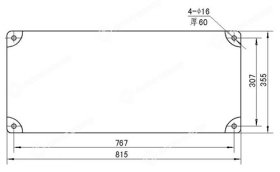

Constructional Characteristics

GMS series grinder keeps up all the merits of traditional colloid mills such as well-designed construction, simple operation, low noise, easy servicing, small in size and light in weight etc. Moreover, it has also the advantages of wide adaption, easy variation in speed, and a different type of motors may be replaced to suffice the demands for special materials to be processed.

- The main parts of this machine are made of high-grade stainless steel, hence are corrosion-proof and nonpoisonous.

- The critical parts of the mill, i.e. rotor and stator, are processed precisely by adopting of advanced technology. The grinding gap(clearance between rotor and stator) may be micro-adjusted by means of gap-regular ring, on which an index dial is prepared for easily reading of scales. This mechanism can be controlled conveniently and so the quality of products will be ensured satisfying.

- According to the different products processed, the rotor and stator made of different material may be selected. The whole machine could be assembled or disassembled easily.

- The nominal revolving speed and its variable range may be ordered by customer according to different uses of this machine.

- There is fixing device on the main grinding base, the gap-regulating ring, to ensure the stable distance during the machine working.

- It is matched with the water cooling system, to ensure the nature of material

- The customer can choose to use common motor or explosion-proof motor.

- The colloid grinder has the character of reasonable structure, stable performance, simple operation and maintenance.

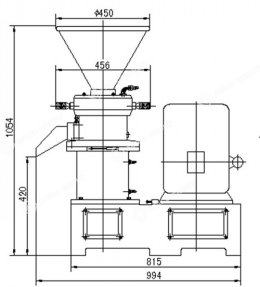

Drawing

Installation size

Mounting & Operating Rules: Routine Servicing

- Mount the mill on a perfect leveling surface of concrete foundation and screw down into a permanent position by foundation bolts.(according to the operating site and conditions, it may also be put on even surface only without any fixing.)

- Check every screw whether it is fastened.(Note: the motor central screw is left-handed.)

- Turn the rotor slightly by accessory wrench before switching on of the drive motor to check if it touch or catch the stator. If so it is, strictly forbid to take into operation.

- Inspect the power supply system. It must be 3-phase alternating current, and with the mill body grounding properly. The rotating direction of motor should correspond to the arrow marked on the mill base(clockwise)

- Put through cooling water on to the inlet nozzle 2, but if the speed does not exceed 4000rpm, cooling is unnecessary in general.

- Start the motor at a touch and go in order to check if any abnormal noise or vibration exists. If so, stop immediately and repair, then test again.

- Clean the mill after processing timely, Cleaning must be carried out in the running condition, and firstly, turn the gap-regulating ring 6 counterclockwise to an angle not less than 90C.

Main Parts and Package:

|

|

|

Learn more about our fruit juice making machine.

Tel: (86) 372 5965148

Fax: (86) 372 5951936

E-mail: info@peanutbuttermachines.com