AGICO have a group of professional employees who devoted into technology research and development. We established an integrated system of product research and development, manufacturing, marketing and service which takes the market as the goal orientated. In order to ensure the quality of products and services, we have passed the ISO9001:2000 quality system certification.

AGICO have a group of professional employees who devoted into technology research and development. We established an integrated system of product research and development, manufacturing, marketing and service which takes the market as the goal orientated. In order to ensure the quality of products and services, we have passed the ISO9001:2000 quality system certification.

According to your local use, we will recommend different models and production peanut butter grinder machinery and equipment to the users. And guide the user how to operate simply, make finished product conforms to the requirements of the customers.

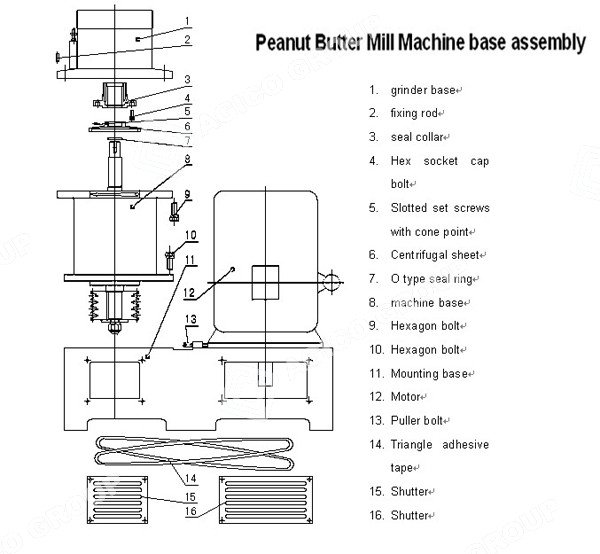

Part Maintenance Matters of peanut butter mill machine:

1. Check the circuit control system and rotation system regularly to make sure they are working normal. Check all the fixing bolts and adjusting bolts to avoid any loosing contract. Adding suitable amount of the lubricant oil to necessary parts.

2. Regulate the grinding gap according to the required particle size of product processed. Regulating must be carried out in the running condition.

3. Requirements of materials before grinding:

a) This peanut butter mill machine can only grind the wet materials but not the dry solid.

b) Materials must be filtered or selected before entering into the mill if impurities exist in it. Particle size of material should be less than 1mm after filtering and hardness not higher than HV309. Strictly forbid the iron or stone particles getting into the mill head, or may cause damage.

4. Constantly pay attention to the conditions in operation and running period. Stop the peanut butter mill machine to check it if any abnormality appears.

Tel: (86) 372 5965148

Fax: (86) 372 5951936

E-mail: info@peanutbuttermachines.com